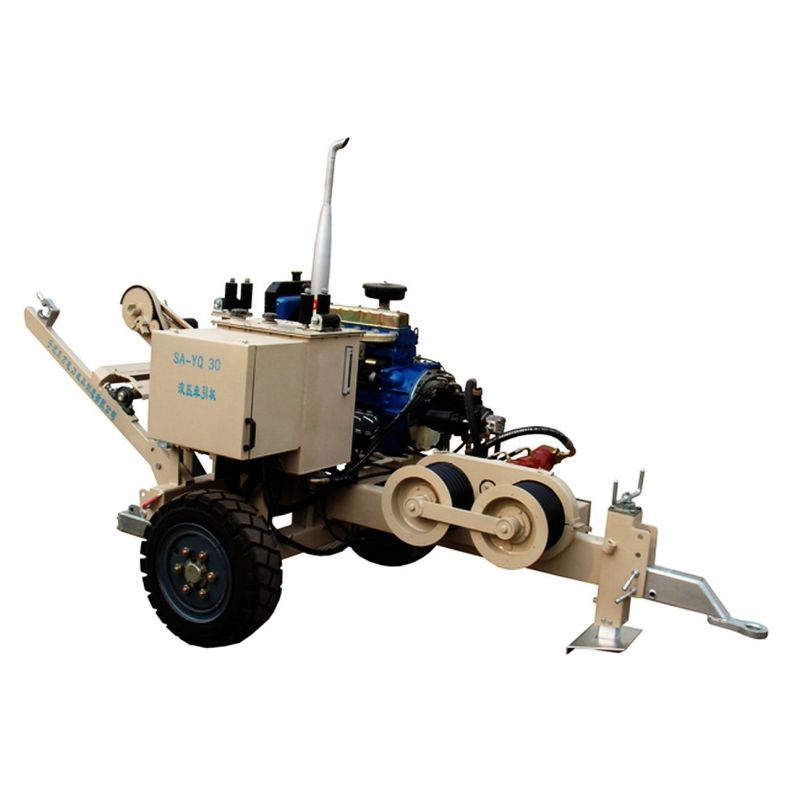

OEM Tool For Cutting Armoured Cable Manufacturer – Hydraulic Traction Stringing Equipment for Overhead Transmission Line Construction Hydraulic Traction Equipment – Donghuan Power

OEM Tool For Cutting Armoured Cable Manufacturer – Hydraulic Traction Stringing Equipment for Overhead Transmission Line Construction Hydraulic Traction Equipment – Donghuan Power Detail:

Product introduction

The product is used for the traction of various conductors, ground wires, OPGW and ADSS during tension setting out.

Infinitely variable speed and pull force control ,the pull in the rope can be read on the line pull gauge .

The max pull for conductor–stringing operation can preset ,automatic overload protection system .

Spring applied –hydraulic release brake acts automatically in case of hydraulic failure ensure to safety .

With hydraulic pulling rope clamp,replacing steel rope conveniently.

With wire rope automatic winding device,automatic rope laying,loading and unloading convenience.

Hydraulic Traction with various traction loads ranging from 3 tons to 42 tons have a complete range.

Engine : Cummins water cooled diesel engine.

Main variable pump and main motor :Rexroth (BOSCH)

Reducer :Rexroth (BOSCH)

Main hydraulic valve : Rexroth (BOSCH)

Matched reel:GSP1100-1400

Hydraulic Traction Technical Parameters

| Item number | 07001 | 07011 | 07031 | 07041 | 07051 | 07061 | 07065 | 07071 | 07075 | |

| Model | QY-30Y | QY-40Y | QY-60Y | QY-90Y | QY-180Y | QY-220Y | QY-250Y | QY-300Y | QY-420Y | |

| Maximum pull forc (KN) |

30 | 40 | 60 | 90 | 180 | 220 | 250 | 300 | 420 | |

| Continuous pull forc (KN) |

25 | 35 | 50 | 80 | 150 | 180 | 200 | 250 | 350 | |

| Maximum pull force (KM/H) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Bottom of groovr diamere (MM) |

Φ300 | Φ400 | Φ460 | Φ520 | Φ630 | Φ760 | Φ820 | Φ960 | Φ960 | |

| Number of groovr (MM) |

7 | 7 | 7 | 7 | 9 | 10 | 10 | 10 | 11 | |

| Maximum suitable stell rope diamete (MM) |

Φ13 | Φ16 | Φ18 | Φ20 | Φ24 | Φ30 | Φ32 | Φ38 | Φ45 | |

| Maximum through connectors diamete (MM) |

Φ40 | Φ50 | Φ60 | Φ60 | Φ63 | Φ75 | Φ80 | Φ80 | Φ80 | |

| Engine power/speed (KW/RPM) |

31/ 2200 |

60/ 2000 |

77/ 2800 |

123/ 2500 |

209/ 2100 |

243/ 2100 |

261/ 2100 |

298/ 2100 |

402/ 2100 |

|

| Dimensions (M) |

3.2 x1.6×2 |

3.5 x2x2 |

3.8 x2.1×2.3 |

3.5 x2.1×2.5 |

5.5 x2.2×2.6 |

5.7 x2.3×2.6 |

5.8 x2.4×2.6 |

5.9 x2.5×2.9 |

6.1 x2.6×2.8 |

|

| Weight (KG) |

1500 | `2500 | 3000 | 4300 | 7500 | 8000 | 9000 | 11500 | 14800 | |

| matching wire rope tray | Mode | GSP 950 |

GSP 1400 |

GSP 1400 |

GSP 1400 |

GSP 1600 |

GSP 1600 |

GSP 1600 |

GSP 1900 |

GSP 1900 |

| Item No. | 07125A | 07125C | 07125C | 07125C | 07125D | 07125D | 07125D | 07125E | 07125E | |

Product detail pictures:

Related Product Guide:

We've one of the most advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for OEM Tool For Cutting Armoured Cable Manufacturer – Hydraulic Traction Stringing Equipment for Overhead Transmission Line Construction Hydraulic Traction Equipment – Donghuan Power , The product will supply to all over the world, such as: Seattle, Thailand, Benin, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

A good manufacturers, we have cooperated twice, good quality and good service attitude.